Honeycomb mesh belts and open rod belts: solutions for thermal, washing and food processes

WBT’s GP and FMC belts combine robust design, open mesh structures and sprocket-driven control to deliver durability, hygiene and reliable performance in food processing.

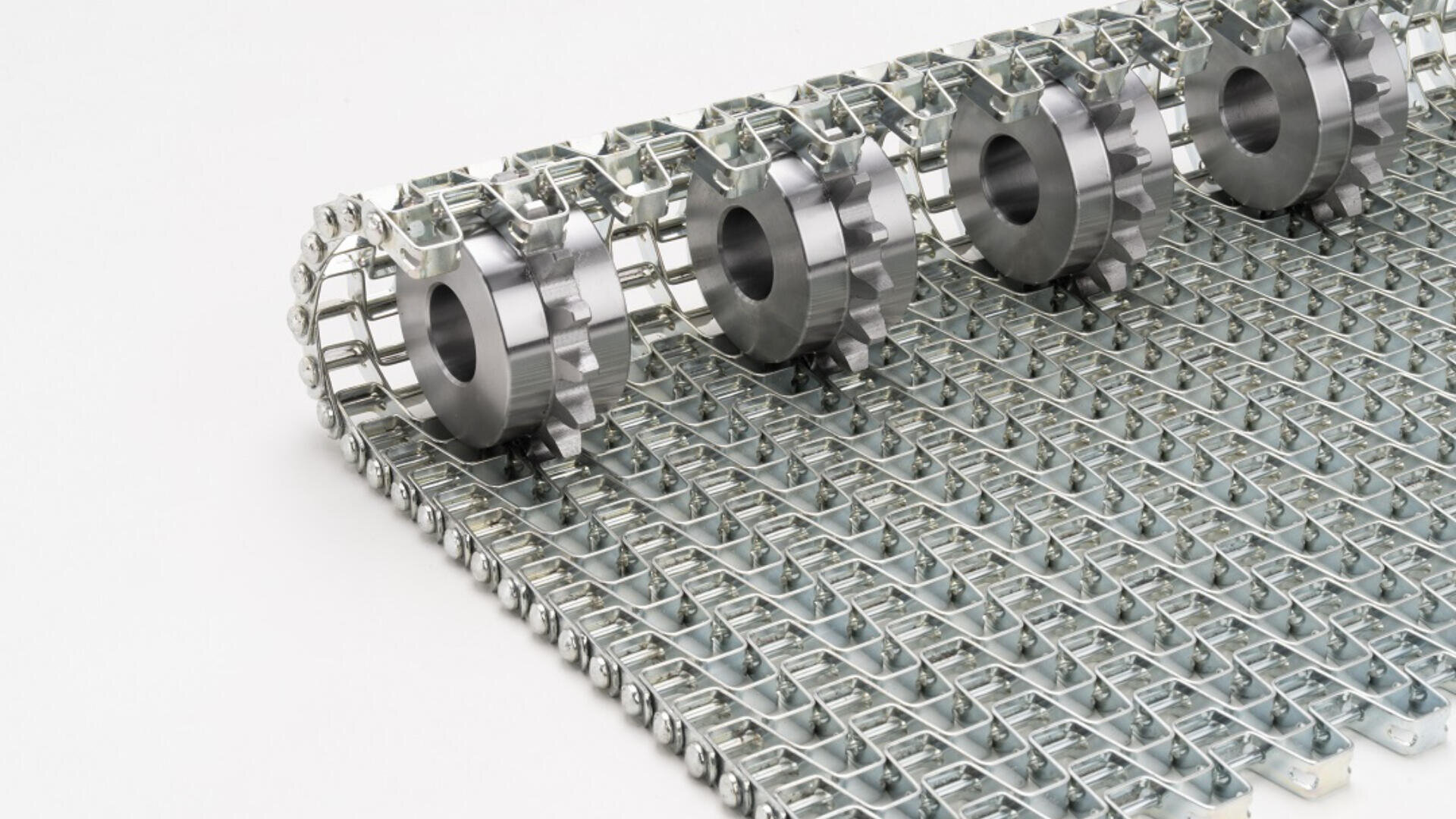

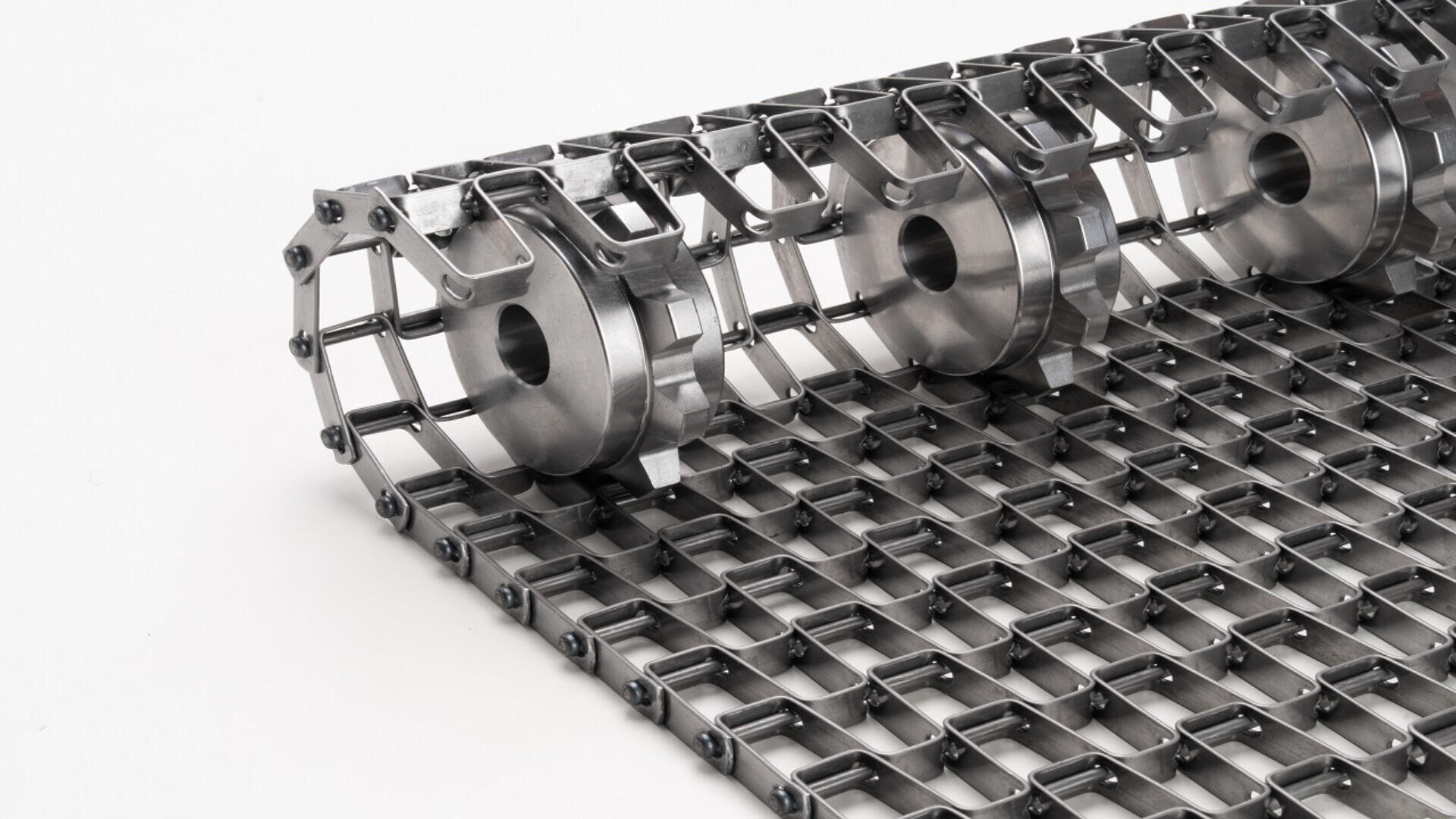

GP belts: engineered for strength and structure

WBT’s GP belts feature a honeycomb open mesh design and are driven by sprockets for maximum control. These belts are extremely robust, capable of supporting high loads and widths of up to 5000 mm.

They are specifically designed for applications requiring tray or pan handling, such as baking sandwich loaves (pancarré), tramezzini, cakes and breadsticks.

Beyond baking, GP belts are also ideal for:

- Washing: trays, bins and general containers.

- Shrink-wrap ovens: for packaging processes with thermal film.

- Pasteurizers: handling jars and food containers such as jams or preserved foods.

The open honeycomb structure ensures excellent heat transfer and drainage, making these belts suitable for processes requiring both thermal control and cleanliness. Their solid build and positive drive system ensure reliable operation even in the most intensive production environments.

Each GP belt is custom-built from stainless or carbon steel and undergoes rigorous in-motion testing before delivery.

The belt’s modularity allows it to be easily integrated into various machine designs or retrofitted into existing lines.

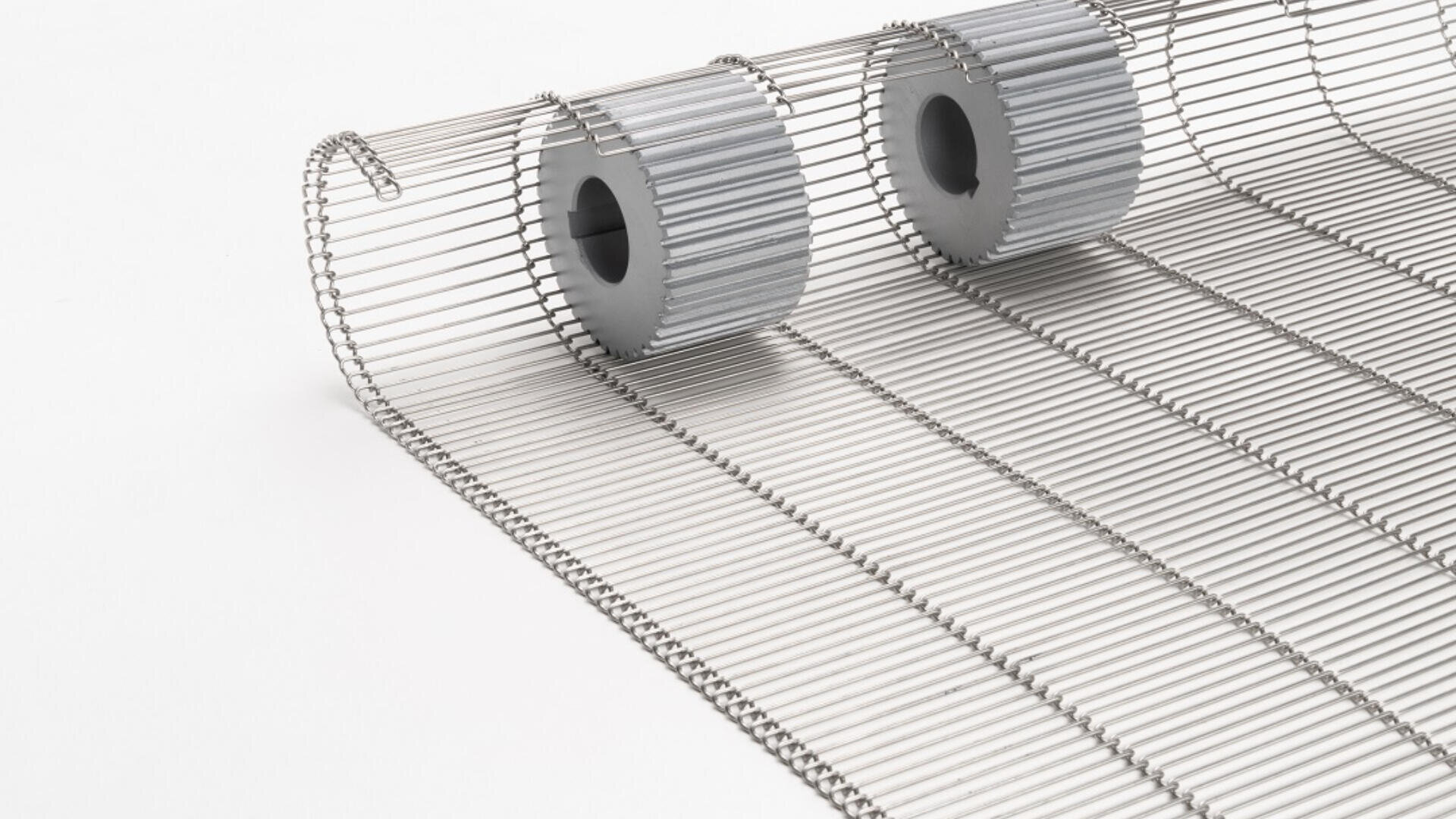

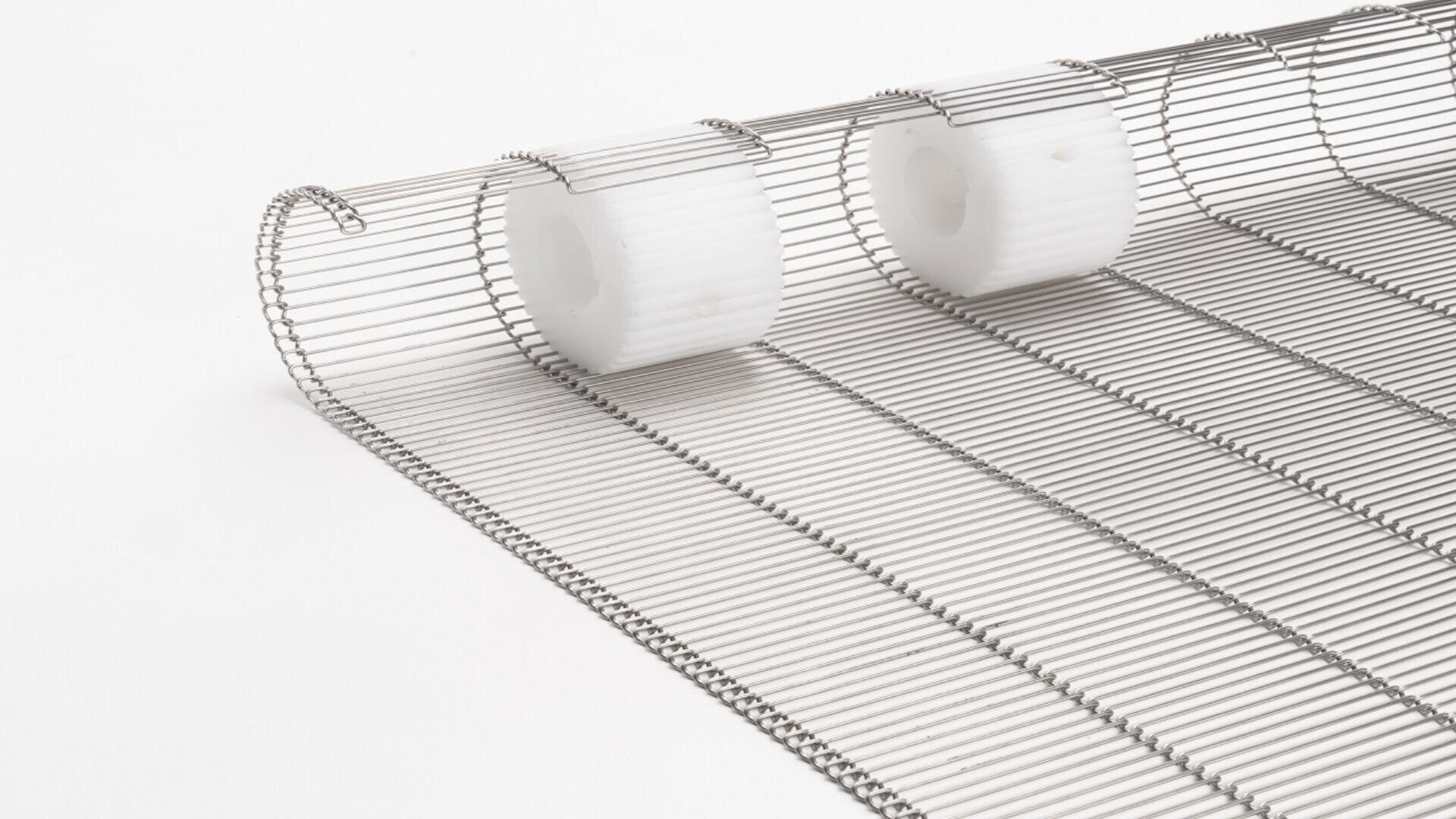

FMC belts: precision and cleanliness for direct contact processes

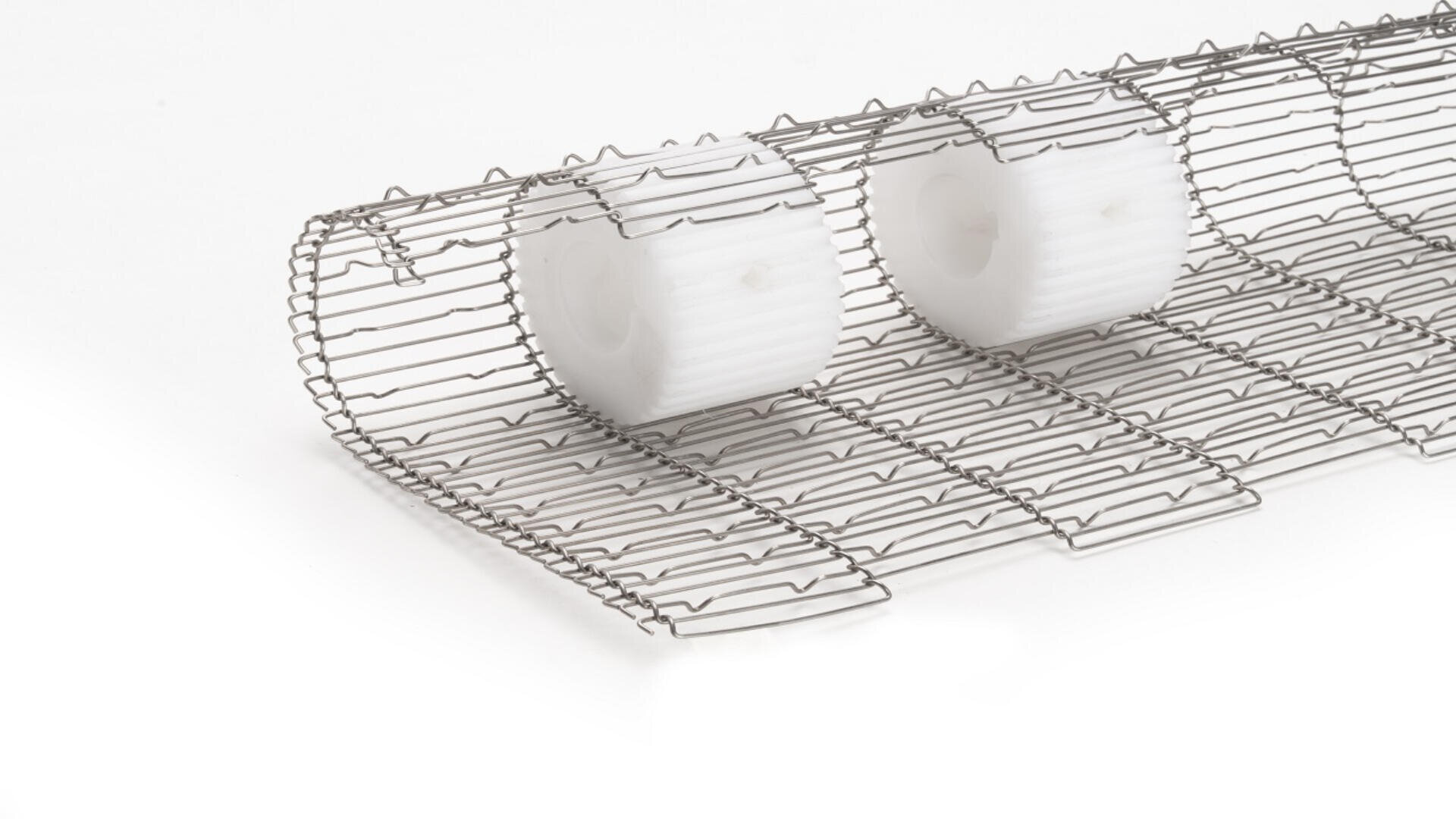

FMC and FMCD belts from WBT are open mesh belts with up to 90% opening and sprocket-driven traction.

They are designed for direct food contact and optimized for processes that demand minimal product contact and easy cleaning.

These belts are particularly effective in:

- Direct baking or crisping: ideal for pizzas, focaccia, flatbreads (pinse) and sliced bread.

- Coating and glazing lines: chocolate, sugar and various toppings or seeds.

- Frying lines: perfect for products like stuffed olives, arancini or battered vegetables.

With minimal contact area and an open structure, FMC and FMCD belts reduce sticking and facilitate efficient transfer of heat or oil.

Their design ensures not only performance but quick maintenance and sanitation between production cycles.

The key difference between the two lies in the mesh configuration: FMC belts are engineered for maximum openness and minimal surface contact, while FMCD belts feature a more compact drive design, ideal for tighter installations or where enhanced belt control is needed.

When timing matters, count on WBT

In food production, every second counts. Equipment needs to be reliable, cleanable and above all, ready to work.

At WBT, we understand the pressure of tight deadlines, shifting production demands and the critical importance of uptime. That’s why we design belts that not only meet technical standards but anticipate the real-world challenges of industrial bakery and food processing environments.

We are more than a manufacturer. We are a responsive, expert partner that works alongside your team to identify the right solution for your specific needs. Whether you’re facing an urgent breakdown, planning a system upgrade or exploring more efficient production methods, our belts - and our experts - are ready.

WBT combines over 30 years of field experience with the flexibility of a tight-knit, skilled team. We move fast, without sacrificing precision.

We listen before we recommend. And we always deliver with commitment and care.

Come meet us at iba 2025 - Stand 10 / H39 to explore our belts up close and discuss your challenges with our specialists.

Or get in touch today and let us help you turn urgency into opportunity!