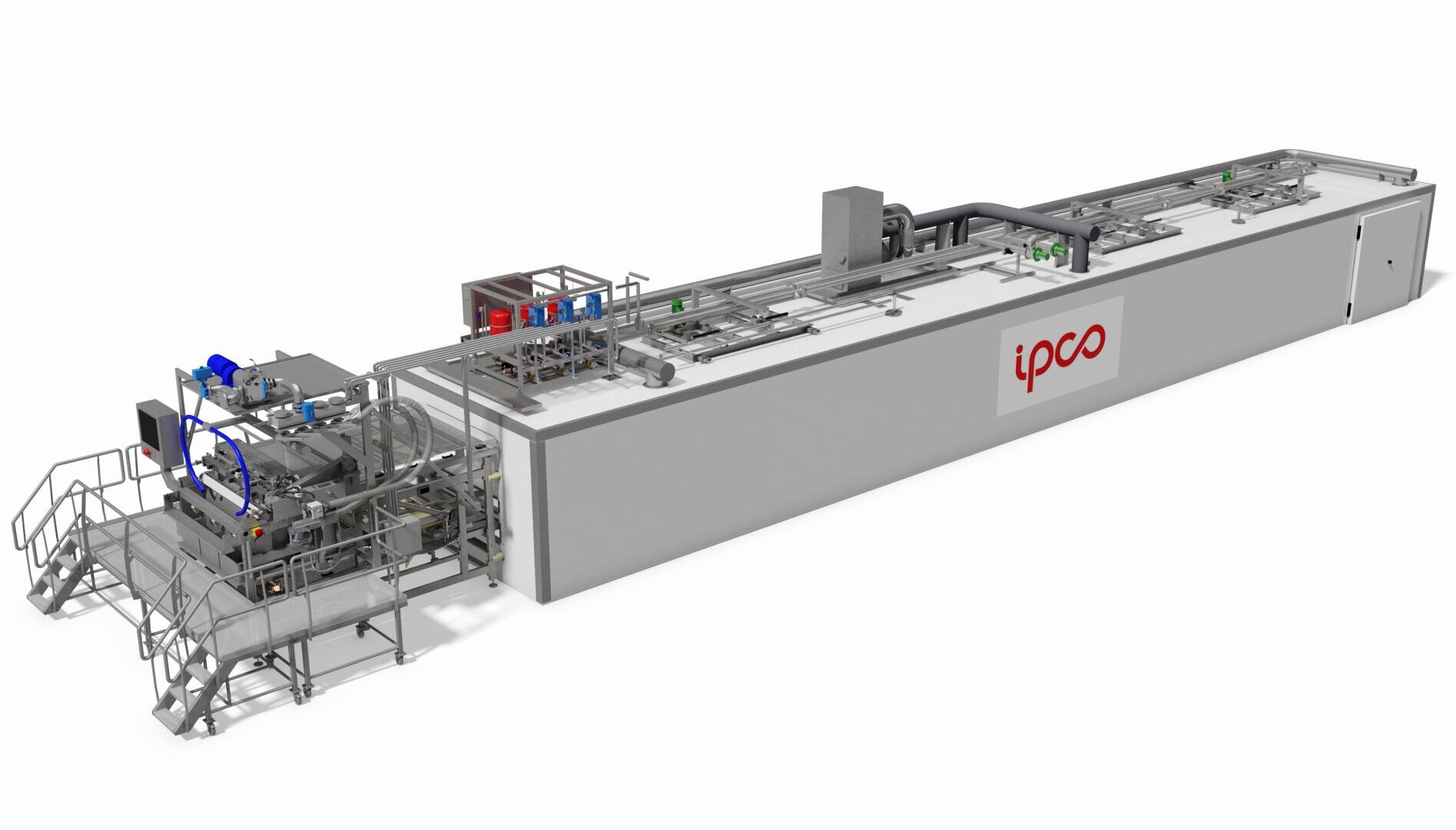

IPCO CCM triple pass steel belt system for chocolate - versatile molding solution

The IPCO triple pass steel belt chips/drops/chunks molding (CCM) system offers outstanding production versatility. It enables high-capacity production of chocolate chips, drops, and chunks in a wide range of sizes, from a single, high-performance line.

The IPCO triple pass steel belt chips/drops/chunks molding (CCM) system offers outstanding production versatility. It enables high-capacity production of chocolate chips, drops, and chunks in a wide range of sizes, from a single, high-performance line.

This innovative moulding line is based on the rotary depositor module (RDM), an extremely reliable unit with low maintenance requirements. The module features an exchangeable outer shell enabling production of chips in sizes from 30,000 to 300 pcs/kg.

The triple pass cooling process enables throughput rates of more than 3,000 kg/hour from a compact system with a low floorspace requirement: the total length is approximately 35 m.

The line also incorporates a separate strip extruder module and software adjustable servo cutter capable of up to 1,000 cuts a minute.

The drops are deposited onto a 1,500 mm steel belt conveyor and transported through the cooling tunnel. They are carried back on the underside of the return stand before being removed onto an FDA PVC conveyor. They travel back through the tunnel for a third time and are discharged for downstream processing.

Why choose IPCO’s unique range of chocolate production machinery?

-

High-productivity, small-footprint systems: Our triple pass process solutions enable high throughput rates from systems with a compact footprint

-

Rapid product changeover: Switch chip sizes in under 30 minutes by changing the depositor shell on our Rotary Depositor Modules.