Process equipment

Discover VolGor’s advanced process equipment—Sugar Grinding Mill, Homogenizer-Disperser, Margarine Plasticizer, and Vertical Cone Mixer—engineered to meet your unique production needs. We offer tailored solutions, designing custom equipment to solve any processing challenge.

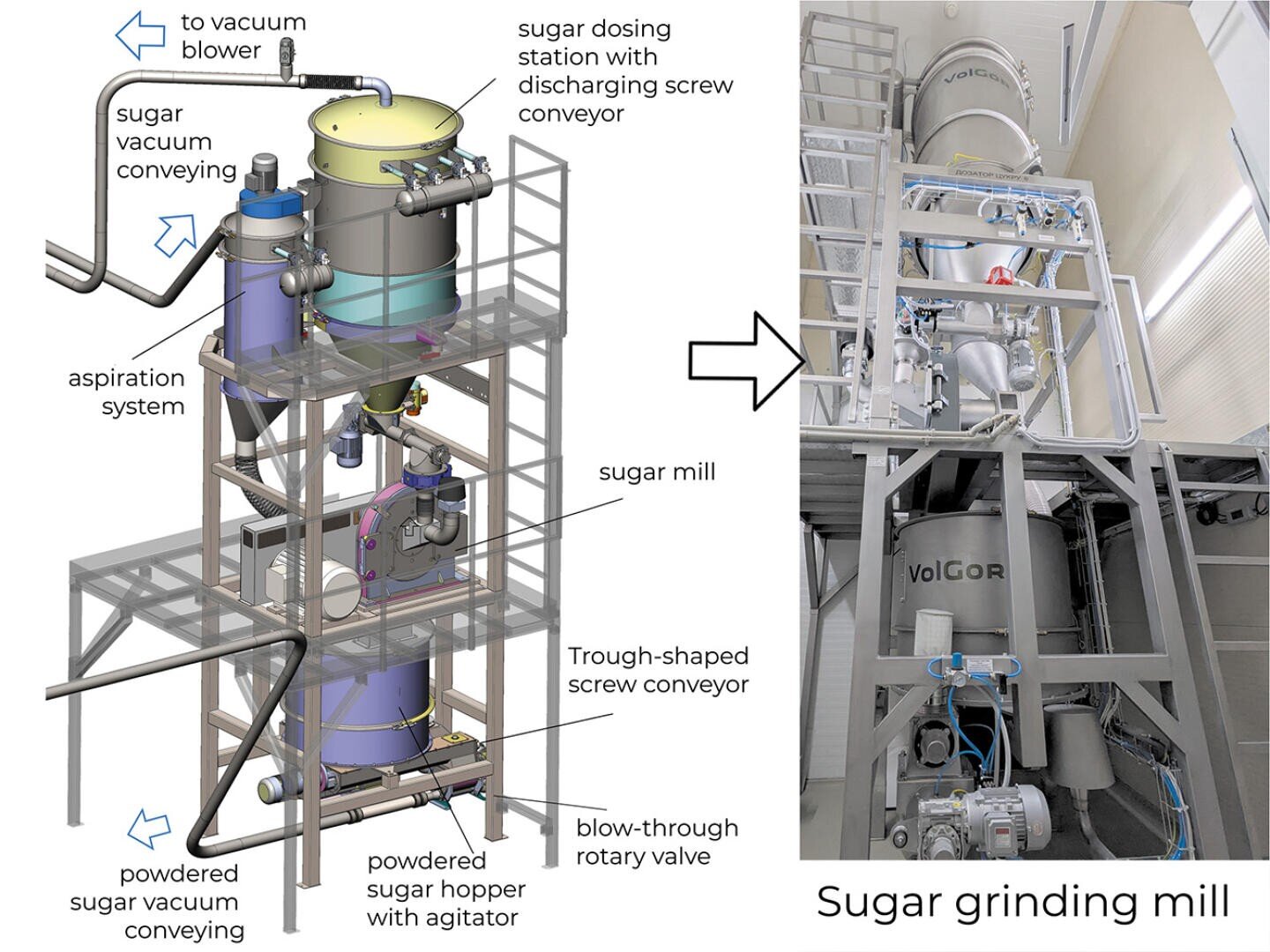

Sugar Grinding Mill for Powdered Sugar Production

Powdered sugar is one of the key components in many confectionery products. For mass production, it is much more convenient for companies to produce powdered sugar in-house rather than purchasing it ready-made.

Our company has extensive experience in manufacturing complexes for powdered sugar production.

Grinding of Defective Cookies and Bakery Products

Unfortunately, no confectionery factory is immune to defective products. Therefore, their processing is a relevant task that significantly reduces raw material losses.

For certain types of confectionery waste, we offer effective solutions — Complexes for grinding defective cookies.

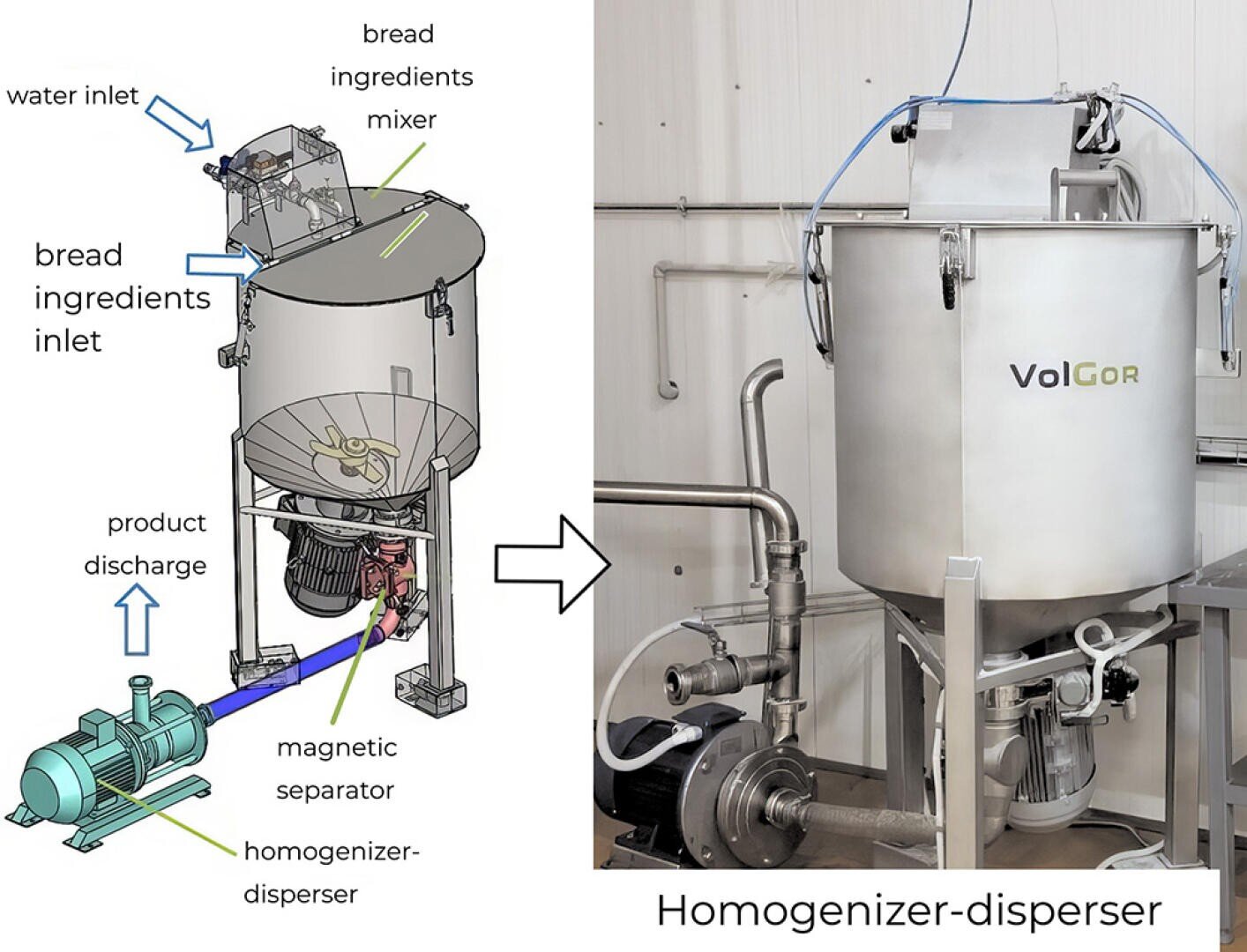

System for Producing Homogeneous Mixture of Bakery Products and Water

The homogenization of bakery products with water is carried out in two stages.

In the mixer, components are loaded in the required proportions and pre-ground. In the homogenizer-disperser, the primary grinding takes place.

The mixer is mounted on a weighing system, which ensures the accurate loading of raw materials in the correct proportions. Water is supplied through a dosing-tempering device that mixes incoming streams of hot and cold water to maintain the desired temperature.

At the mixer outlet, a magnetic separator captures ferromagnetic impurities, and a mesh filter captures mechanical impurities.

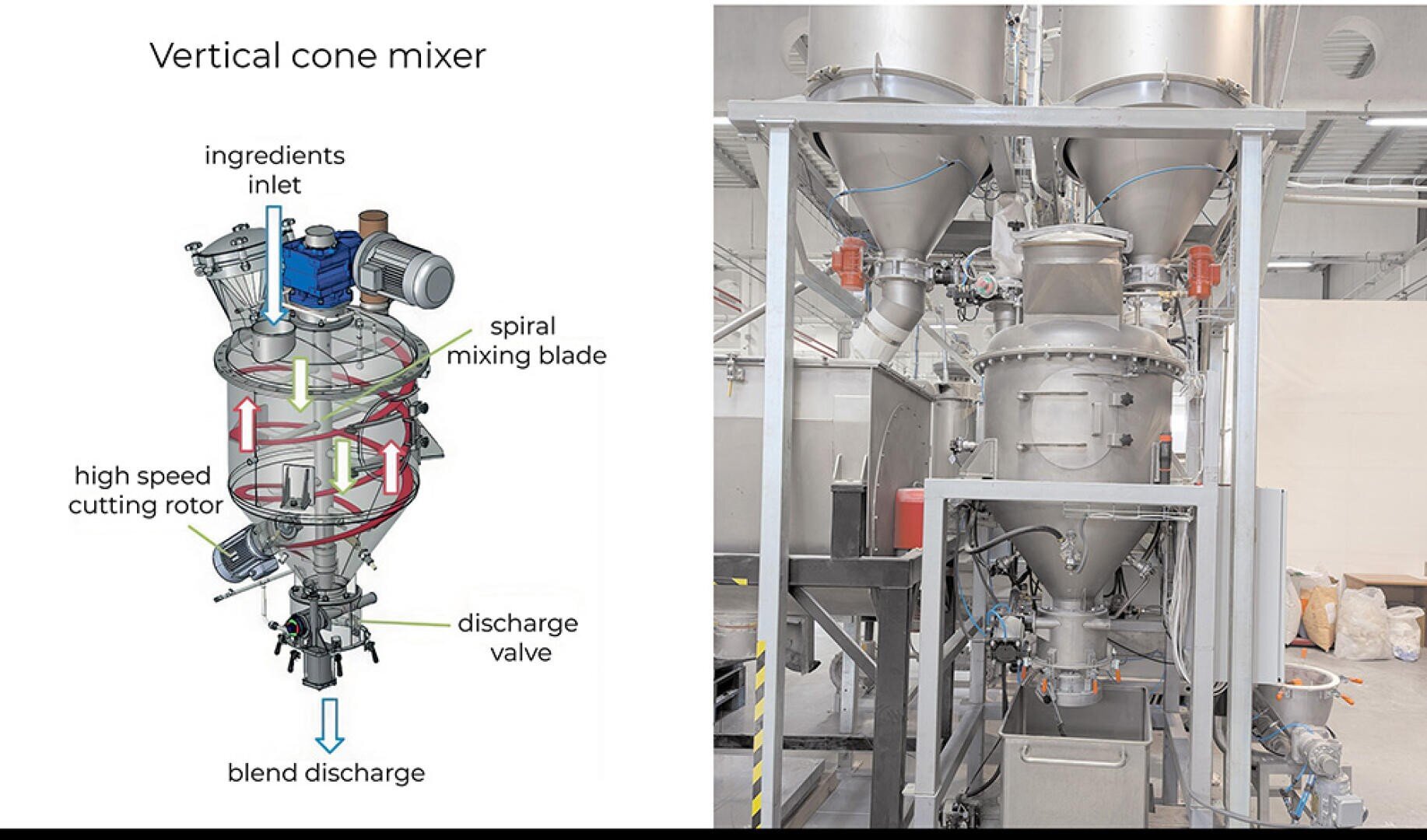

Vertical Ribbon Mixers

Vertical ribbon mixers are structurally more complex but provide more complete product discharge compared to horizontal mixers.

The ribbon spiral has only one direction, ensuring upward movement of the product. The product falls downward due to gravity. Due to the movement of product layers in opposite directions, effective mixing is achieved.

Storage for Liquid Components

For mixing liquid products, we manufacture tanks with low-speed frame agitators. They are used, for example, to maintain the stability of already prepared emulsions or suspensions, or for the preparation of starter cultures.

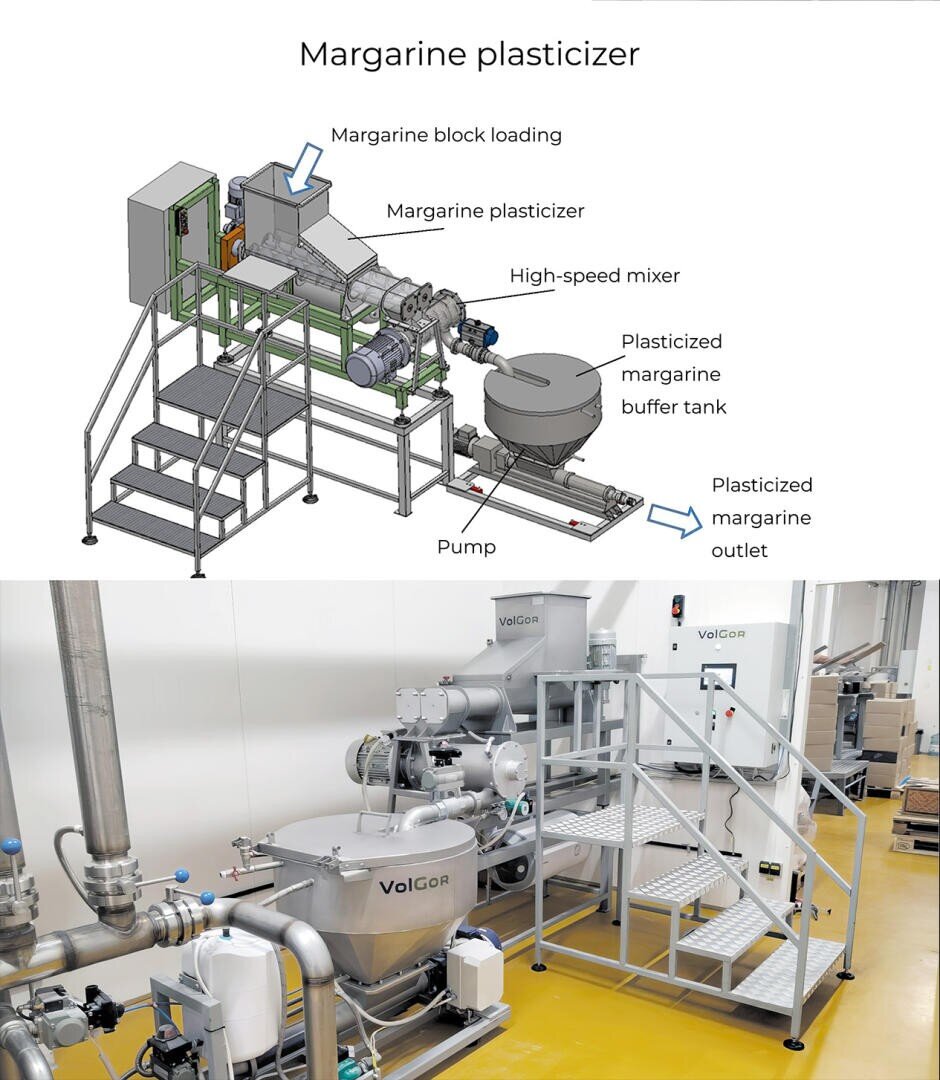

Plasticization

Optimizing the Fat and Margarine Preparation Line

Margarine and confectionery fat are among the main raw materials for confectionery factories. They are typically supplied in the form of chilled blocks. In this state, they cannot be loaded into processing equipment, as this can damage the working parts of mixing devices. Therefore, they are first subjected to plasticization — the transformation into a paste-like mass.

Traditionally, plasticization is carried out in so-called fat melters by heating the product. However, fat melters have several significant drawbacks:

-

Heating the product to relatively high temperatures, accelerating oxidation and rancidity;

-

High energy consumption;

-

Low production efficiency.

We manufacture a margarine plasticization system that eliminates the above-mentioned drawbacks. In our system, plasticization is primarily achieved mechanically, the temperature of the plasticized margarine does not exceed 30°C, and the system's capacity, with relatively compact dimensions and energy consumption, reaches up to 2500 kg/h.